Matt McAndry, Business Development Manager at Glidevale, a division of Building Product Design Ltd, argues that roof space ventilation is essential to avoid condensation resulting from improving levels of insulation in refurbished properties.

Local authorities and housing associations throughout the UK are working to improve the energy efficiency of their existing housing stock. Common upgrades include window replacement and external wall insulation alongside increasing the levels of loft insulation. However, while these remedial measures improve levels of insulation at ceiling level, as a by-product, the average air temperature within the dwelling is increased, allowing the air to carry more water vapour. When warm moist air passes through the ceiling to a cold loft void, harmful condensation is inevitable. This is especially true if the loft access hatch is not upgraded and other routes through to the loft space are not suitably sealed. Condensation, taking place out of sight of the occupier, can cause serious damage to decoration, loss of insulation effectiveness and timber decay. It is therefore important for contractors working on insulation upgrades to refurbished properties to consider the need for roof space ventilation, in order to avoid storing up condensation problems for the future.

Roof space ventilation products suitable for retro-fitting in conjunction with loft insulation upgrades can be broadly split in two categories – eaves ventilation and slate and tile ventilators.

Eaves ventilators available include fascia and soffit ventilators. However, for public sector refurbishment projects, soffit and fascia ventilators have a number of disadvantages. For example, existing soffit or fascia boards may be old and too weak to tolerate ventilators being fitted, which could result in the need to replace the soffit or fascia. Fitting soffit or fascia ventilators also requires scaffolding the property. Where fascia and soffit ventilators are fitted in conjunction with loft insulation upgrades, it is also essential to fit rafter ventilators to ensure a clear air path between the roof underlay and insulation of all types of eaves. All of these could incur unnecessary additional expense as well as extra time required to complete the work.

Slate and tile ventilators offer a viable and more cost-effective alternative. They are easy to install in existing buildings by simply replacing one slate or tile with a ventilator, causing minimum disruption to occupants. They can also be easily fitted by the attic insulation contractor at the same time as the loft insulation, requiring only a ladder to access the roof in cases. There is no need to fit rafter ventilators as slate and tile ventilators are installed above the level of the insulation. Slate and tile ventilators are a universal solution for all house types, regardless of the eaves detail, and it is easy for the site surveyor to see that the work has been carried out. There is also no need to disturb the eaves detail and risk having to replace soffit or fascia boards.

Glidevale offers a broad range of slate and tile ventilators that are driving rain tested and are ideally suited to local authority and housing association properties. Its range is available in a wide range of profiles, colours and sizes, matching products of all tile manufacturers in the UK and Ireland.

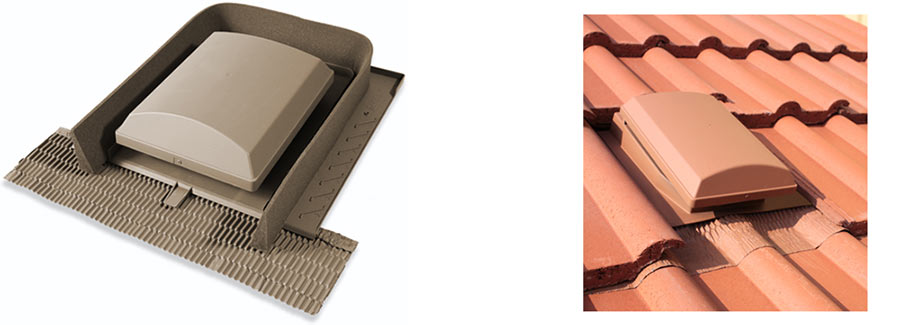

In particular, its Versa-Tile G5 ventilator has a universal design, suiting virtually all interlocking single lap tiles*. It can be used for all roof space ventilation requirements and incorporates AluFlash, a mouldable and flexible adhesive-backed flashing at the leading front edge to ensure the weathering of the ventilator. It is available in five UV-stable colours of red, brown, grey, terracotta and red streak.

Extension sleeves are available to ensure that there is a continuous, permanent weatherproof path from the roof void to the outside without impairing the weatherproof function of the roof. Underlay opening protectors maintain the function of the underlay where it is cut. Any moisture which might penetrate the roof covering higher up the slope is safely diverted around the opening.

Fitting roof space ventilation at the same time as upgrading loft insulation is a simple operation for the insulation contractor – and will save the need for a roofing contractor having to carry out the same job later, when condensation problems have become apparent and housing stock has been damaged.

Glidevale provides technical advice on roof space refurbishment projects. Its service includes a free site survey to establish roof construction, soffit details and roof covering, a specification service to meet all regulatory requirements and recommendations based on the Glidevale range of ventilation products.

* with the exception of plain tiles, clay single pantiles, interlocking slates and certain small format tiles.